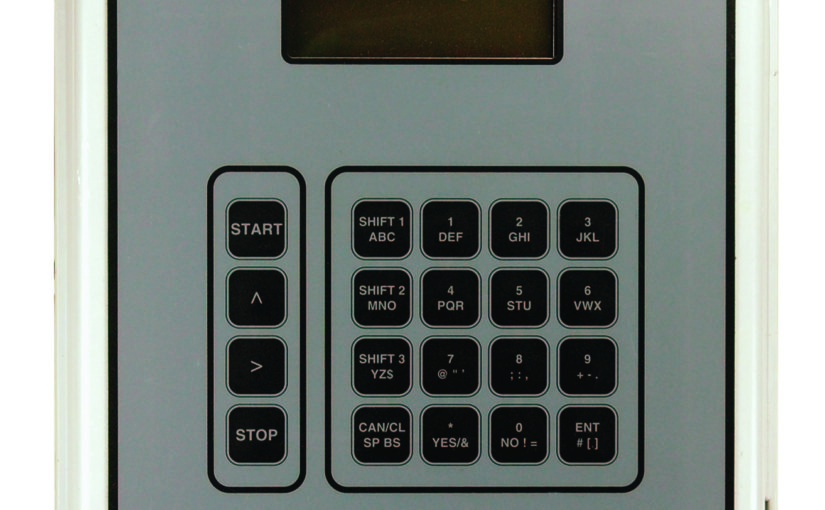

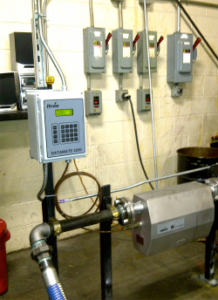

The 800 series register is the latest of four multi-function devices specifically designed for petroleum distribution and industrial process industries. Some models allow automatic preset deliveries via mechanical valve and Weights and Measures approved ticket printing.

Models

The 800 Series Registers consist of the Model 830 Series and the Model 840 Series. Model 830 Series registers are in tenths and the Model 840 Series registers are in units.

Models 831 and 841 are direct reading resettable registers with the basic non-resettable totalizer.

Models 832 and 842 are the basic 830 and 840 features plus a preset register that provides automatic deliveries. The operator sets the register for the desired quantity from the front panel. The flow will cut off automatically at the exact volume desired when used in conjunction with either a mechanical valve or a solenoid actuated valve. There are two preset models available, a single trip for one stage shutoff or a double trip for two stage shutoff (delivery decreases, then the final shutoff stops the delivery).

Models 833 and 843 are the basic 830 and 840 features plus a printer register that prints a receipt or ticket showing the readings before and after delivery. The register locks the ticket during delivery to prevent fraud. Providing two letter wheels in the register makes it possible to print a letter code on the ticket to identify the flowmeter or truck. These letter wheels can print any single letter or combination of two letters from A to J, omitting I. Additionally, three serial number wheels are provided in the register to number each ticket consecutively from 000 to 999. There are four printer models available:

- Accumulative Face Up (most commonly used): Prints beginning reading and the final reading

- Accumulative Face Down (for outside use): Prints beginning reading and the final reading

- Zero Start Face Up (for larger deliveries): Prints all zeros and the actual delivery

- Zero Start Face Down (for larger deliveries): Prints all zeros and the actual delivery

Models 834 and 844 are printer-preset registers that combine the features of the other registers. They contain the preset quantity control plus the printed ticket features.

Features

- Standard eight digit non-resettable totalizer, five digit delivery display, four preset and five or six digit printer

- Measurement in Gallons, tenths of gallons, litres, dekalitres, pounds and kilograms

- High visibility ¾” wheels

- Long life, precision die cast Zamac printer wheels provide clear, sharp, easy to read tickets

Literature

Tech Sheet →

O&M Manual →

Parts List →

Liquids: wines, distilled and blended liquors, bottled and canned soft drinks, resins, propionic acid, fructose, solvents, rhodimet, calcium chloride, sugar, grape juice, ethyl acetate, molasses, edible beef tallow, tomato puree, animal fat, hydrogenated soybean oil, mineral spirits, water, waste oil, oil, latex, acetonitrile, cream, aquaeous ammonia, slurry, toluene, oleum, glycol-water, pulverized asphalt flakes, varnish, waste water, methanol, sodium hydroxide and milk whey.

Liquids: wines, distilled and blended liquors, bottled and canned soft drinks, resins, propionic acid, fructose, solvents, rhodimet, calcium chloride, sugar, grape juice, ethyl acetate, molasses, edible beef tallow, tomato puree, animal fat, hydrogenated soybean oil, mineral spirits, water, waste oil, oil, latex, acetonitrile, cream, aquaeous ammonia, slurry, toluene, oleum, glycol-water, pulverized asphalt flakes, varnish, waste water, methanol, sodium hydroxide and milk whey.