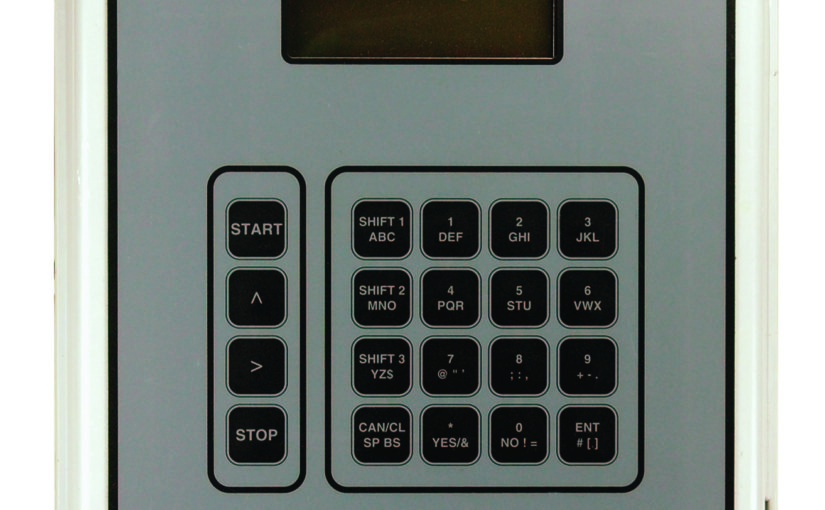

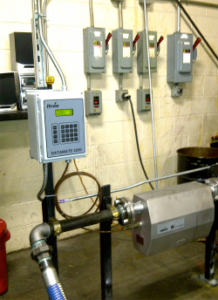

The Neptune E4000 electronic register automates transaction operations for deliveries of LPG, distillate fuels, and other commercially distributed liquids through flow meters on bulk delivery trucks. Designed for compatibility with emerging automation technologies, the E4000 offers the ability to modernize truck metering operations today and provides a platform for data collection technology tomorrow. Its improved accuracy and efficiency mean less loss, providing a fast return on investment and safeguarding future profits.

Smarter Today

- Easy to use, menu driven display

- Start with simple pump and print (imitate your mechanical register)

- Electronic temperature compensation (accurate, rapid response)

- Stand-alone pricing (print invoices directly from the truck)

- Ten products, ten prices

- Configure register from laptop computer

Smarter Tomorrow

- Add data collection devices (hand held, laptop, wireless) without the need for additional register hardware.

- No requirement for early commitment to proprietary technology.

- Interface with popular industry office software packages.

However you manage transactions, Neptune value will help you do more today…and much more tomorrow.

Literature

Installation Manual →

Tech Sheet →

Parts List →

E4000 Configuration Program →

Quick Start Guides

Operator Guide, LPG →

Operator Guide, Refined Fuels, Preset Valve →

Operator Guide, Refined Fuels, No Valve →

Supervisor Guide →

Using the Configuration Program →

USB Instructions →

Flash Programming Software

How to Determine the Flash Version of the E4000 Main Board

RB Version – Instructions, programming application, and files

HEX Version – Instructions, programming application, and files

Serial Protocol

EA.01.XX.E →

EA.02.XX.X →

Liquids: wines, distilled and blended liquors, bottled and canned soft drinks, resins, propionic acid, fructose, solvents, rhodimet, calcium chloride, sugar, grape juice, ethyl acetate, molasses, edible beef tallow, tomato puree, animal fat, hydrogenated soybean oil, mineral spirits, water, waste oil, oil, latex, acetonitrile, cream, aquaeous ammonia, slurry, toluene, oleum, glycol-water, pulverized asphalt flakes, varnish, waste water, methanol, sodium hydroxide and milk whey.

Liquids: wines, distilled and blended liquors, bottled and canned soft drinks, resins, propionic acid, fructose, solvents, rhodimet, calcium chloride, sugar, grape juice, ethyl acetate, molasses, edible beef tallow, tomato puree, animal fat, hydrogenated soybean oil, mineral spirits, water, waste oil, oil, latex, acetonitrile, cream, aquaeous ammonia, slurry, toluene, oleum, glycol-water, pulverized asphalt flakes, varnish, waste water, methanol, sodium hydroxide and milk whey.